High-Tech Maker Space Opens at The Cooper Union with $2M from IDC Foundation

POSTED ON: December 17, 2020

The Cooper Union announced the opening this week of a new state-of-the-art maker space, made possible with $2 million in leadership funding from the IDC Foundation. Giving Cooper students remote and, eventually, in-person access to advanced fabrication equipment—from 3D printers to robotic arms to virtual-reality technologies—the IDC Foundation Art, Architecture, Construction, and Engineering (AACE) Lab will support projects across the institution’s three disciplines.

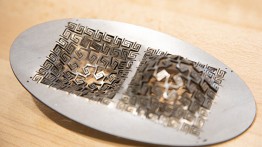

Cooper was awarded the funding to build an interdisciplinary maker space in 2018 after several departments collaborated to submit a grant proposal to the IDC Foundation, a New York-based charitable organization that provides scholarships, fellowships, and grants to educational institutions for students in the design, engineering, and construction fields. The facility enables students to fabricate intricate components, artwork, prototypes, and models from a broad range of materials thanks to high-precision digital tools, which include laser cutters, CNC routers, 3D printers, a waterjet cutting machine, a vinyl cutter, a vacuum forming machine, and more.

“The main purpose of the AACE Lab is to provide a collaborative fabrication environment for Cooper’s entire student body,” said Harrison Tyler, the AACE Lab’s director. “It really is our first truly school-wide fabrication resource. I’m excited for the future of this space and for seeing what kind of work comes out of having an architect, an artist, and an engineer all working in the same environment.”

The AACE Lab is housed within the institution’s iconic 161-year-old Foundation Building. Sam Anderson, an alumnus and adjunct faculty member of Cooper’s Irwin S. Chanin School of Architecture, led the design effort to convert a former lobby space on the fourth floor into a high-tech maker facility embodying the spirit of cross-disciplinary collaboration. The lab is entered through a large, custom glass partition and adjoins with Cooper’s existing Art and Architecture Sculpture Shop to form a direct connection between the two, giving students the flexibility to work with both newer digital fabrication tools and traditional woodworking and metalworking machinery.

“We really wanted it to have a feeling of openness and inclusion, so that people felt very comfortable coming in,” said Anderson, whose team included Kayt Brumder and Alice Colverd, two fellow Cooper alumni at his practice, Samuel Anderson Architects. Zhenia Dementyeva and Willem Smith-Clark, both fifth-year Cooper architecture students, also assisted with architectural drawings and creating a virtual model of the lab.

One of the design challenges for the team was marrying the ethos of a leading-edge, all-school workshop to the historic space of the Foundation Building. In 1975 the entire interior of the building was reconstructed by the influential architect John Hejduk, former dean of Cooper’s school of architecture. The AACE Lab’s glass partition and much of its technical infrastructure were designed to preserve the existing geometry of the space while reimagining how it could serve students. “We have a lot of reverence for John Hejduk and what he did for the Foundation Building,” said Anderson. “We felt it was really important to be respectful of Hejduk’s original design but at the same time not to just copy what we imagine he would do.”

A pilot phase of the AACE Lab launched in a temporary location last February, staying open to students for only a few weeks before the COVID-19 lockdown. The digital fabrication equipment, however, proved remarkably conducive to virtual learning and working with social distancing protocols in place, and has even been put to use to benefit the wider community. As the health crisis hit New York City hospitals in March, a group of Cooper staff and faculty volunteers organized an initiative to 3D-print and laser-cut 1,500 protective face shields, which they donated to local health workers. Since then, students have also been able to take advantage of the equipment via a remote project submission and contactless pick-up system.

“Students can submit a file online, a lab technician sends the file to the machine, and it’ll turn out more or less exactly the same as if a student was doing it in person, so I think it ends up working really well both for what we're dealing with right now and hopefully where we'll be in the near future,” explained Tyler, who has been overseeing construction on the permanent fourth-floor space since June. For now, the facility will continue operating via remote submission, with the goal of eventually opening for socially distanced and limited in-person access once it is safe to do so.

“This represents a huge step forward for all three schools,” said Laura Sparks, president of The Cooper Union. “The AACE Lab not only equips our students with the latest tools, but it also expands the imaginative possibilities for creating, making, experimenting, all of which are such an essential part of what a Cooper education is about. I’m eager to see how it inspires students’ ideas and projects.”

“The opening of the AACE Lab is an exciting development for collaboration between art, architecture, construction, and engineering,” said Raymond R. Savino, President of the IDC Foundation. “Fueling innovation through such collaboration among construction-related fields is the focus of the IDC Foundation. We are especially pleased that this facility has already proven to be so adaptable to current conditions, and we look forward to seeing what novel ideas Cooper students generate with this new resource.”

Additional support for the AACE Lab was provided by The Board of the Higher Education Capital Matching Grant Program: Hon. Deborah J. Glick, Mr. Robert F. Mujica, and Ms. Lisa Clare Kombrink.